EVA foam modification: from shoe midsole to yoga mat, manufacturers can produce soft and durable lightweight foam products

The metallocene catalyst technology can provide EVA (ethylene vinyl acetate) foam products with excellent mechanical properties and elasticity. These innovative polymer modifiers with different melt indexes and densities can be adapted to a variety of foaming processing techniques, and are lighter to wear while maintaining the performance of the shoe material.

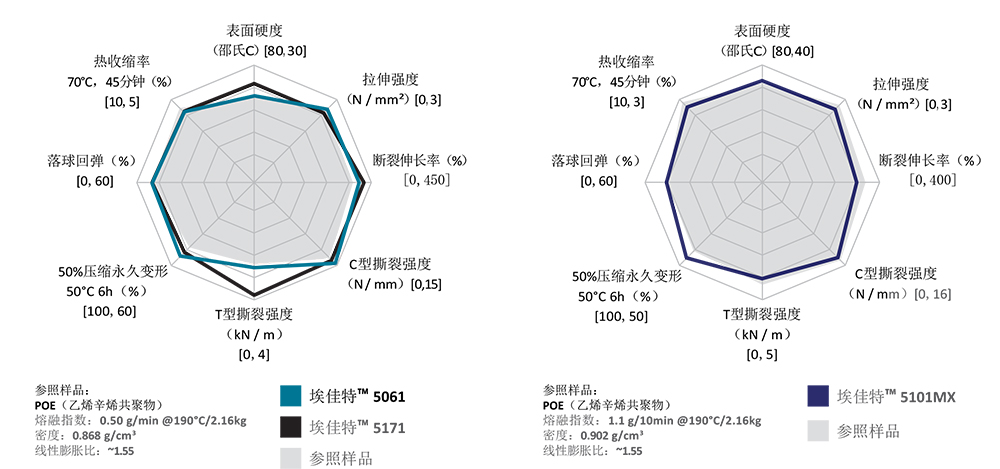

Excellent foaming performance: Compared with the reference modifiers, Exact™ 5061, Exact™ 5171 (left picture) and Exact™ 5101 MX (right picture) are in key characteristics (Such as compression set, surface hardness and elongation at break) show excellent performance.

| Ingredients | phr |

| EVA (28%VA) | 70 |

| Exact™ or reference sample | 30 |

| Features | Exact™ 5061 | Exact™ 5101MX | Exact™ 5171 | Exact™ 5371 | The test method is based on |

| Melt index, 190°C/2.16 kg g/10 min | 0.5 | 1.1 | 1 | 5 | ASTM D1238 |

| Density g/cm3 | 0.868 | 0.9 | 0.868 | 0.868 | ASTM D1505 |

| Peak melting temperature℃(℉) | 54 (129) | 94 (200) | 55.2 (131) | 57.7 (136) | ExxonMobil Method |

| Vicat softening temperature℃(℉) | 55.8 (132) | 91.2 (196) | 54.2 (130) | 503 (122) | ExxonMobil Method |

| Hardness (Shore A/D) | 70A | 39D | 70A | 68A | ExxonMobil Method |

| Tensile stress MPa (psi) | >10 (>1500) | >28 (>4100) | >7.8 (>1100) | >55 (>760) | ExxonMobil Method |

| Elongation at break % | >800 | >800 | >800 | >800 | ExxonMobil Method |